[2024] TO BE REAL

ToBeReal empowers bioeconomy projects by deploying Technical, Business, Regulatory and Social services

MooV’s main activity in ToBeReaL is to provide logistics optimisation and decision-support services for bioeconomy projects, modelling value chain networks to identify the most efficient and sustainable configurations.

ToBeReaL’s support services are specifically tailored to address the unique needs of bioeconomy projects, offering a targeted and strategic approach. ToBeReaL provides comprehensive assistance with a particular focus on the critical areas where innovative initiatives often encounter challenges in scaling effectively. Each selected project will be paired with a dedicated mentor from the ToBeReaL consortium, who will guide and support you throughout the entire service process.

[2023] ROBOCOOP

In the ROBOCOOP project , MooV plays a key role in the modelling and optimisation of bio-based value chains.

Specifically, MooV is applied to define the optimal supply chain configuration for each demonstrator case (olive, grape, or stone fruit), integrating logistics, transport, and processing decisions to minimise mobilisation costs while maximising throughput and sustainability.

Robocoop EU project link

[2022] BIOTRANSFORM

Within BIOTRANSFORM, MooV offered decision support for supply chain and logistics network design and optimisation for two European regions.

Andalusia (Spain) on olive tree pruning towards bioplastics

Karlovy Vary (Czechia) on food waste towards biogas

Full report

[2021] QUALISEA - Sustainable seaweed supply chains

MooV services the development a strategic planning and decision-making model for seaweed supply chains from sea-to shore & shore-to-customer.

- Client: ERA-NET COFUND BLUEBIO - Coordinated R&D funding scheme to strengthen Europe's position in the Blue Bioeconomy

- Includes: sea routes, vessel capacity, seaweed cultivation locations, on-shore existing facilities (e.g. fishery), operational data

[2021] BBTWINS - Agri-food Value Chain Digitalisation

MooV assists in the digitalisation of agri-food production processes. Digital twins are a powerful tool that allow to simulate and optimise different scenarios - identifying improvements that really matter.

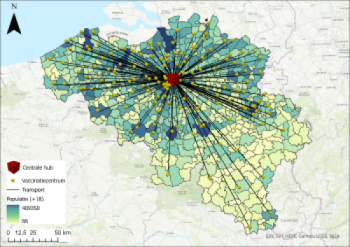

[2021] Covid Vaccine Distribution Strategies

Distribution strategies for the Covid vaccine: Free up hands in hospitals and reduce the risk of losing doses

MooV jointly with UAntwerp showed supply chain optimization supports flexible and adaptable plans for vaccine distribution.

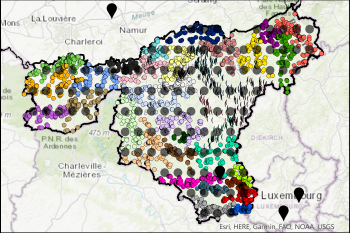

[2021] Rural Parcel Deliveries

MooV tackles last-mile optimisation for postal packages in rural areas

MooV investigates potential efficiency gains of shared cross-dock capacity in delivery of postal packages in rural areas.

- Client: Flanders Logistics Innovation Platform - VIL

- Includes: optimisation of economic, ecologic & societal cost, cross-dock hub - consolidation centers & service points , pilot decision support, parcel typology differentiation

[2019] NIBCON - Matching local biomass feedstock with biorefinery demand

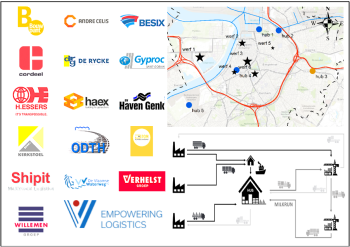

[2019] Building Hubs

Building Hubs reduce logistic costs for building materials with more than 40%.

MooV assessed the relevance of building hubs as a new business concept for building sites.

Press release Full report VIL Website

- Client: Flanders Logistics Innovation Platform - VIL

- Includes: Multiple product and material flows, milk runs, routing, multimodal logistics, mileage, operational and investment costs, scenario comparison as-is & to-be, value-added logistics, load and storage capacities.

- Full report available at VIL

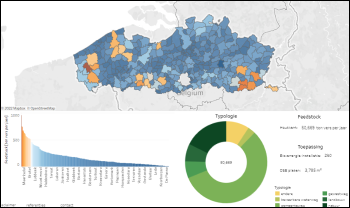

[2018] GRASSIFICATION – MOBILISATION STRATEGIES FOR BIOMASS RESOURCES

Optimising biomass sourcing area reduces mobilization costs. Collection cost can drop below 40€ per tonne.

MooV designs a mobilisation network for grassy material from verge to bio-composites, bio-gas or soil enhancer.

Main Conclusions Full Report Website

- Client: European Union – Interreg – 2Seas

- Includes: geo-data analytics, analysis of the competitive/cooperative landscape, product quality effects and grades, peak supply management, multiple processing options, back-loops, cost analysis.

[2018] BIOMASS HUBS - Optimal mobilisation of biomass from landscape management

Strategic support for the optimal mobilisation of biomass through a network of bio-hubs.

- Client: Flemish Waste & Material Agency - OVAM

- Includes: Cost minimisation, central vs distributed design, storage capacities, multiple end-product options (material – energy), time-effects (seasonality and harvest cycles), GIS-analysis, dash-board interface.

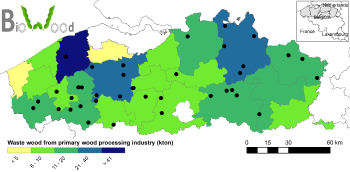

[2017] BIOWOOD - Optimisation of local wood chains for high-value products

MooV assists in the optimisation of the future value chain based on local woody biomass towards high value agro-industrial end products in Flanders.

-

Client: Flemish Agency for Innovation & Entrepreneurship

-

Includes: Cost reduction, reduction of greenhouse gas emissions, multiple end-products, cascading hierarchy of resources, game-theory to reflect conflicting end-user interest, scenario analysis of bio factory locations and capacities.

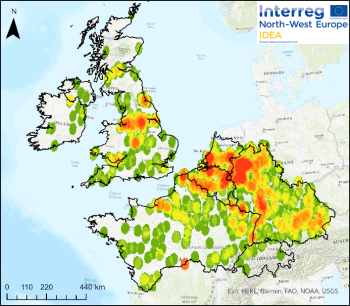

[2017] IDEA – DESIGNING ALGAE-BASED SUPPLY CHAINS

Individual algae growers preferentially need to cluster to match demand of commercial size processing equipment.

MooV defines viable algae-based value chains investigating impact of the size of individual growers, mobility of harvest equipment and regional characteristics (e.g. heating needs).

- Client: European Union – Interreg – North-West Europe

- Includes: Cost minimisation, geo-data analytics, seasonality effects, storage requirements (drying, freezing), multiple end-products (colorants, cosmetics, food, feed), likely production sites, web-based dashboard.